Predictive Maintenance

“Routinely monitoring equipment using predictive technologies and data collecting can help better plan for equipment repairs and save money in downtime and replacement costs.”

Alan Gambsky, CharterAarrowcast Inc. Read More…

As of November 23, 2021, Charter Aarrowcast would like to announce the exciting news that we joined the Charter Manufacturing family. Please see press release.

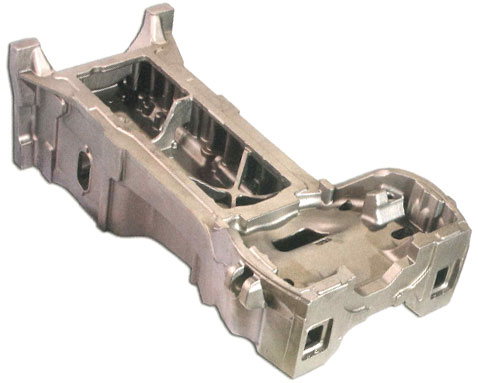

One of the most modern iron foundries of its kind, Aarrowcast, Inc. provides innovative cast metal solutions. Situated on 40 acres in Shawano, Wisconsin (40 miles northwest of Green Bay), the 210,000-square-foot manufacturing facility provides 50,000 tons of ductile and gray iron castings annually to customers in various industries. From government and defense customers to agricultural and heavy truck equipment manufacturers, and an array of companies who need pumps, valves and compressors, Aarrowcast works with our customers to create custom castings that are both efficient and cost effective.

Built in 1978, the original 45,000-square-foot foundry contained two molding lines: a 16 x 20 B & P Roto-Matchblowmatic and a 36 x 40 British Molding Machine (BMM). A 165,000-square-foot expansion added a Laempe automatic core shooter and a 60 x 85 Georg Fischer molding line, which is the largest green-sand molding line in North America.

2015 AFS Plant Engineering Award

2016 AFS Casting of the Year – Honorable Mention

CharterAarrowcast is committed to meet the relevant needs and expectations of the customers, investors, employees, neighbors and continually improve the quality system.

CharterAarrowcast strives to be the preferred source of large gray and ductile iron castings, with the strategy of also offering smaller castings.

This is accomplished by using the process approach and the PLAN-DO-CHECK-ACT (PDCA) cycle for all key performance metrics, with an overall focus on risk-based thinking.

CharterAarrowcast maintains an unwavering commitment to quality. An ISO 9001 certified company, continuous quality assurance is practiced at every phase of CharterAarrowcast’s manufacturing process.

CharterAarrowcast is equipped with dimensional, metallurgical and sand labs.

Metallurgical resources include:

Sand lab resources for tests like:

Dimensional lab resources include:

Aarrowcast is a member of:

CharterAarrowcast is very environmentally conscious and has successfully reduced its landfill usage by 15%. We recycle 41 million pounds of foundry sand, per year. Aarrowcast is OSHA, EPA and DNR Compliant.

“Routinely monitoring equipment using predictive technologies and data collecting can help better plan for equipment repairs and save money in downtime and replacement costs.”

Alan Gambsky, CharterAarrowcast Inc. Read More…